Compact Diode Laser for Near Infrared Methane

Spectroscopy

by Ottillia Ni

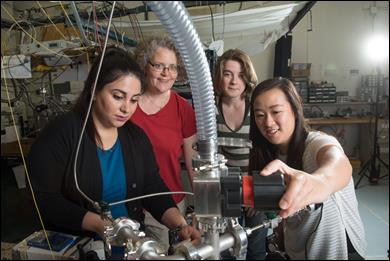

Supervisor: Kristan L. Corwin, Associate Professor of Physics

Kansas State University Physics Department REU Program

This work is partially funded by the National

Science Foundation (NSF) and the Air Force Office of Scientific Research

(AFOSR) through NSF grant number PHYS-1461251.

Any opinions, findings, and conclusions or recommendations expressed in

this material are those of the author(s) and do not necessarily reflect the

views of the NSF or AFOSR.

Project Overview: My

summer research project consists of assembling an external cavity diode laser

at 1.6 microns wavelength using the Littrow configuration. This diode laser is

needed for the development of methane references. The wavelength of the laser

will be tuned to resonance with the 2ν3 transition near 1.63 μm in C-12 methane gas. The methane gas will be placed

inside a hollow-core photonic crystal fiber, and used to develop optical

frequency references. The diode laser will be coupled with an optical fiber to

perform absorption spectroscopy. The

diode laser is constructed with a 250 mW chip, in

order to reach saturation of methane for sub-Doppler spectroscopy. We have

adapted a compact, simple design from 780 nm to 1600 nm, and to higher power.

There are numerous steps that need to occur in order to have the diode laser

successfully assembled running. These

steps include learning multiple new skills that not only greatly contribute to

my research experience, but also enhance my overall physics knowledge. Assembling this laser required learning how

to use Solidworks in order to create precise

drawings, milling and drilling various aluminum pieces that holds the laser

together, soldering wires and cables to connectors needed to power my laser,

and understanding the importance of each part used in the laser. Below are a few pictures recording my progress, the set-up of my work,

and drawings of the laser design.

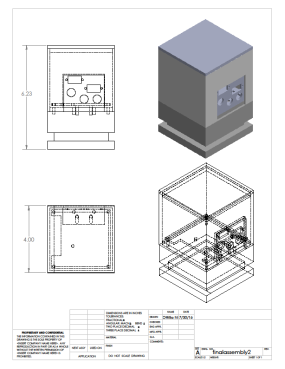

Assembly

drawing of the external set-up of the diode laser designed on Solidworks

The milling

machine used to tap, drill, and mill all the pieces needed to complete the

laser

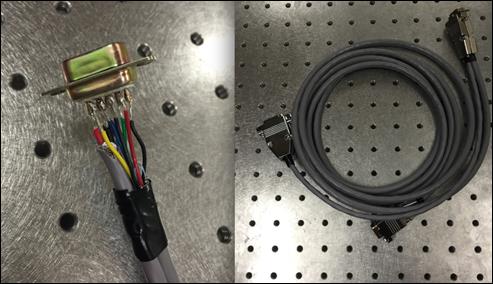

Right: Wire soldered to a 9-pin connector; Left: A cable with three connectors made to connect the laser to the controller (used to power the laser) and the interlock

Machined exterior of the diode laser

Research Description: Want to know more details about my summer research? Click here to download my final presentation in powerpoint and here for the pdf format. You can also click here to access my poster presentation.

About Me: My name is Ottillia Ni and I am currently a rising junior at Willamette University in Salem, Oregon. As a California native, I am thrilled to have had this new experience and opportunity to spend my summer in the Midwest. In the Willamette University Physics Department, I work as an Introductory Physics Lab teaching assistant. In the fall, I will be working as Physics tutor and have been selected as a Webber Scholar, a scholarship program where female science majors teach elementary school students specific fields of science. Outside of the Physics Department, I am an active member of Willamette Amateur Radio Club and serve as an orientation leader for new incoming students in the fall. My hobbies outside the classroom include photography, hiking, travelling, and painting.

Summer in Kansas: If you are interested in seeing some exciting trips and activities aside from the research, click here.