A New Design for a Tunable External Cavity Diode Laser

John W. Lyons

supervisor: Dr. Brett D. DePaola

Kansas State University Physics Department REU Program

This program is funded by the National Science Foundation through grant number PHY-1157044. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

Welcome to the Webpage of John Lyons

We have designed and built a robust tunable external cavity diode laser that is easily constructed from commercial components. It requires only minimal, low tolerance machining, allowing for increased streamlining and ease of construction. The design also allows for any type of laser diode, adding versatility.

Project Overview: Though many commercial designs exist for tunable, external cavity lasers, most are expensive and not user serviceable, giving an advantage to producing custom lasers. Of course, many designs for custom-built lasers also exist, but these usually require extensive, very precise machining. So, our goal was to produce a design that could be made, cheaply, with very little machining. The use of commercial components also limits the amount of machining necessary; the components that must be modified only need simple, easy modifications. We also wanted it to be wired very simply, for easy dis-assembly and re-assembly.

The Final Design:

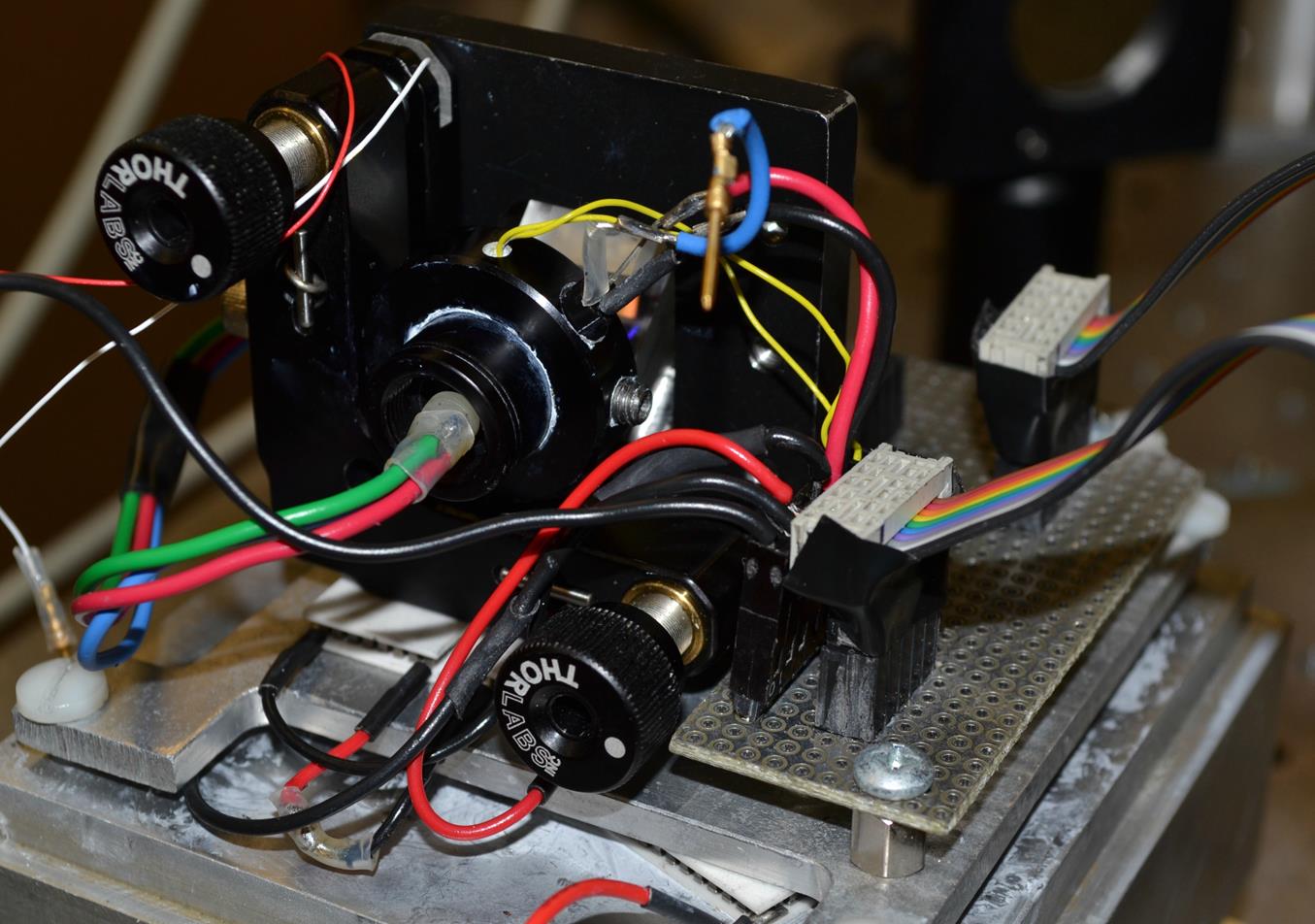

Overall, the finished product looked like:

A cut away, side view:

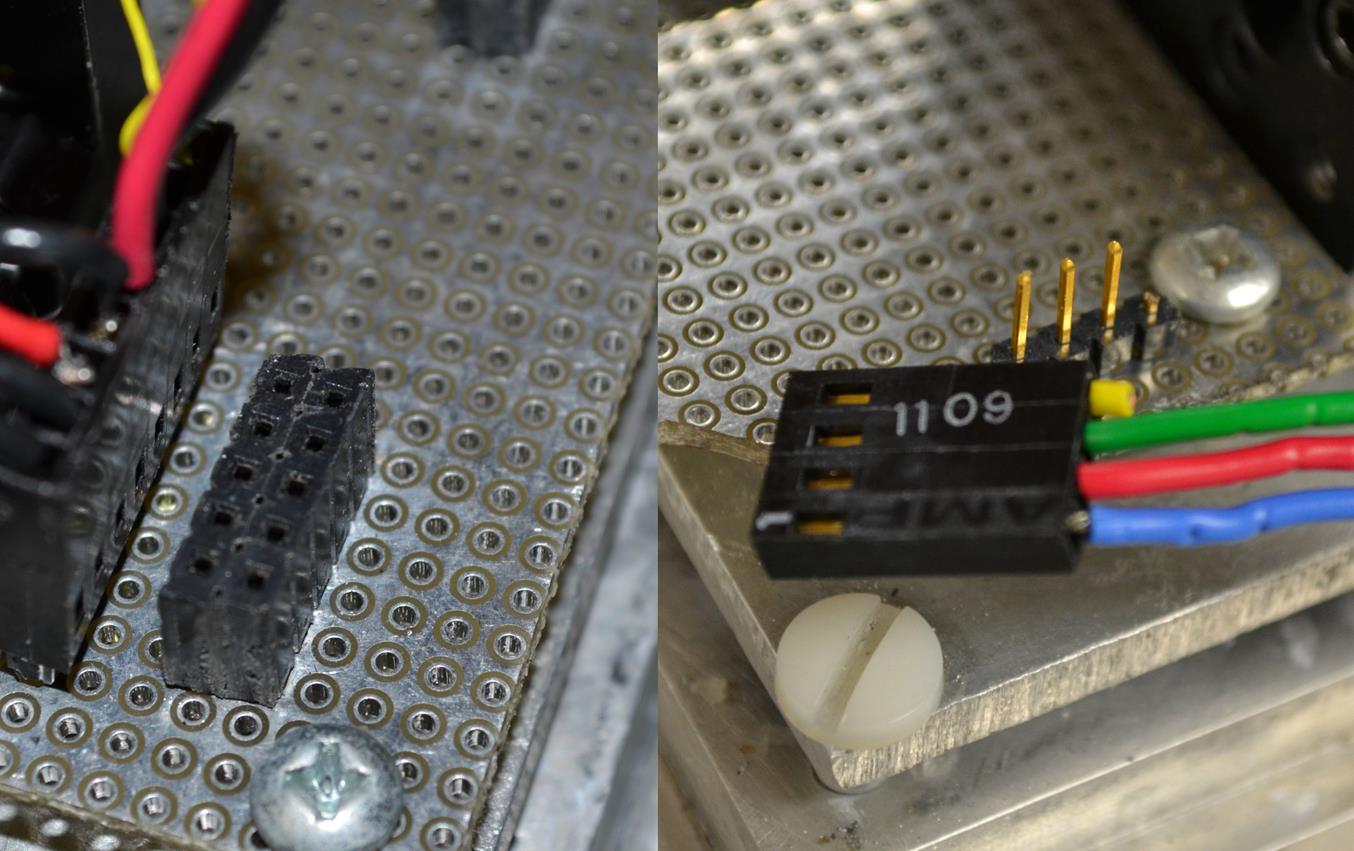

As one can see,

almost all components are attached to sockets that then plug into circuit

boards. These  sockets can be clearly seen in the image to the below.

sockets can be clearly seen in the image to the below.

The sockets attach to a circuit board, where they can be easily disconnected. Total time to completely disconnect the laser is approximately 30 seconds- this is a great aid for troubleshooting and maintenance.

Cooling is accomplished via the two small,

regulated TECs (thermoelectric coolers) (see left) which heat or cool when

current is applied. These are attached to a temperature controller that is

capable of regulating temperature to within a few millekelvin.

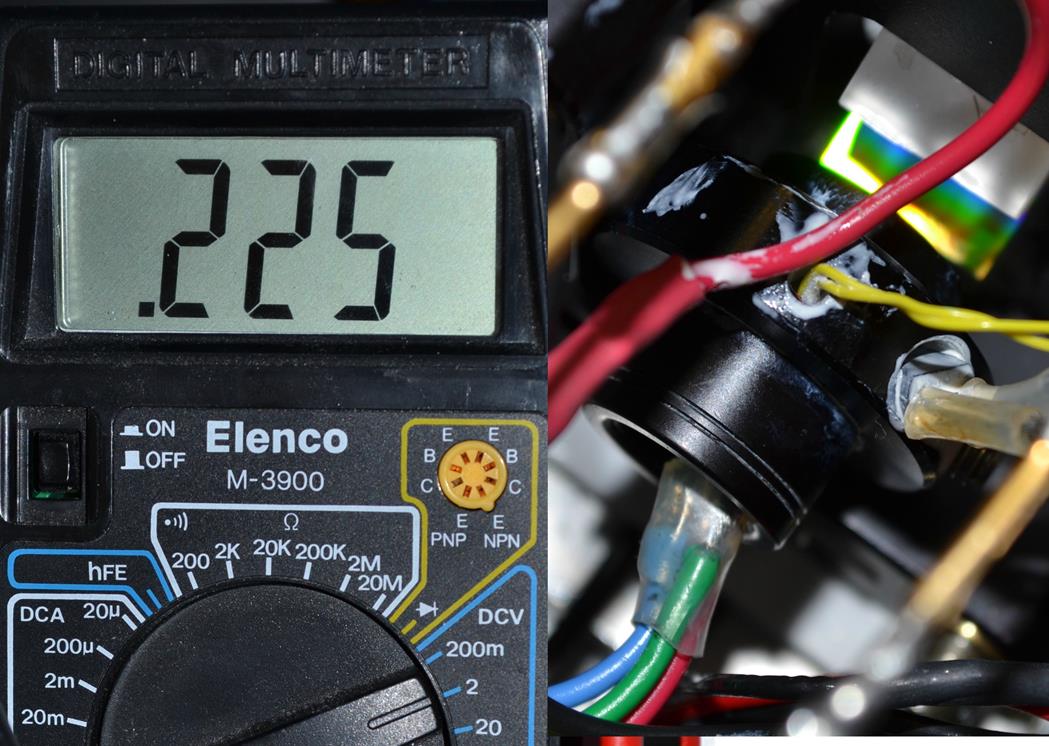

The temperature is measured two temperature sensors,

one that provides a signal to the controller and a second that goes to an

external, human-interpretable output. (In the example shown, that reading is

simply 22.5 degrees Celsius)

The temperature is measured two temperature sensors,

one that provides a signal to the controller and a second that goes to an

external, human-interpretable output. (In the example shown, that reading is

simply 22.5 degrees Celsius)

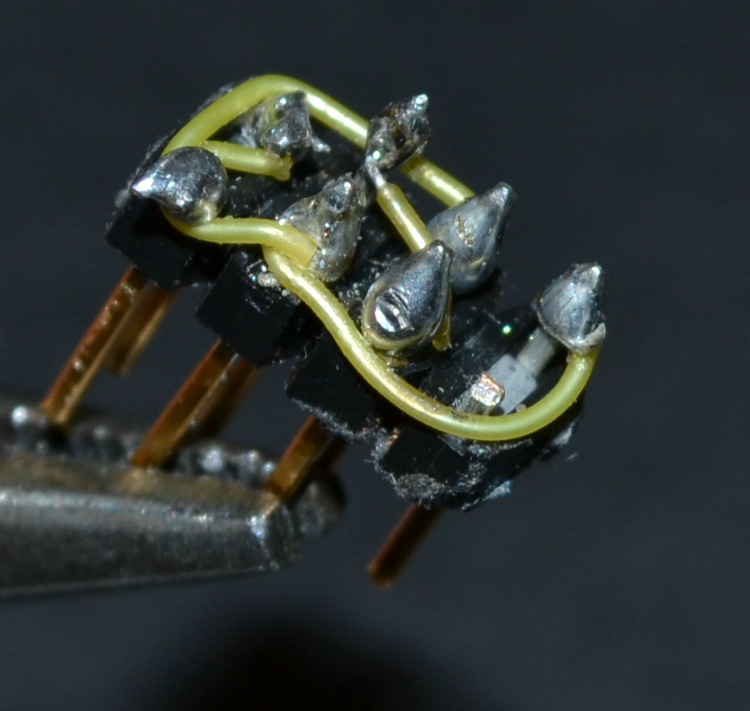

The third large problem that we faced during

construction was dealing with the multitude of laser diodes. Because so many

different diodes exist, different wiring is required for every diode package

configuration. So, we came up with the idea of using “keys”. These keys (like

the one shown) are plugged into an intermediary socket (that can be seen in the

overhead shot). There, they make the necessary connections to account for diode

differences. One simply needs to construct a new key to swap out and use a new

laser diode (a significant improvement over the very large cost to swap out

commercial diodes.)

Applications:

These lasers are useful to any experiment requiring a multitude of cheap, reliable, tunable diode lasers. While the stability and convenience of a commercial laser might be adequate for a single laser, often experiments (such as many here at Kansas State) require multiple, similar lasers. In those cases, using a design such as this to keep costs low, and provide greater flexibility is a large advantage. These lasers are on the order of 30 to 40 times cheaper than commercial models as well, further adding to appeal in budget-conscious laboratories.

Final Presentation: Click here to download my presentation powerpoint and poster formats.

About Me: I'm John Lyons, and at the time of writing I attended Kenyon College, a liberal arts school in rural Ohio. I am a physics major with strong interests in philosophy and social sciences. I also enjoy running, reading, playing piano, singing playing the piano while singing, and exploring the world.