1. Carbon Nanotube (CNT) Deposition

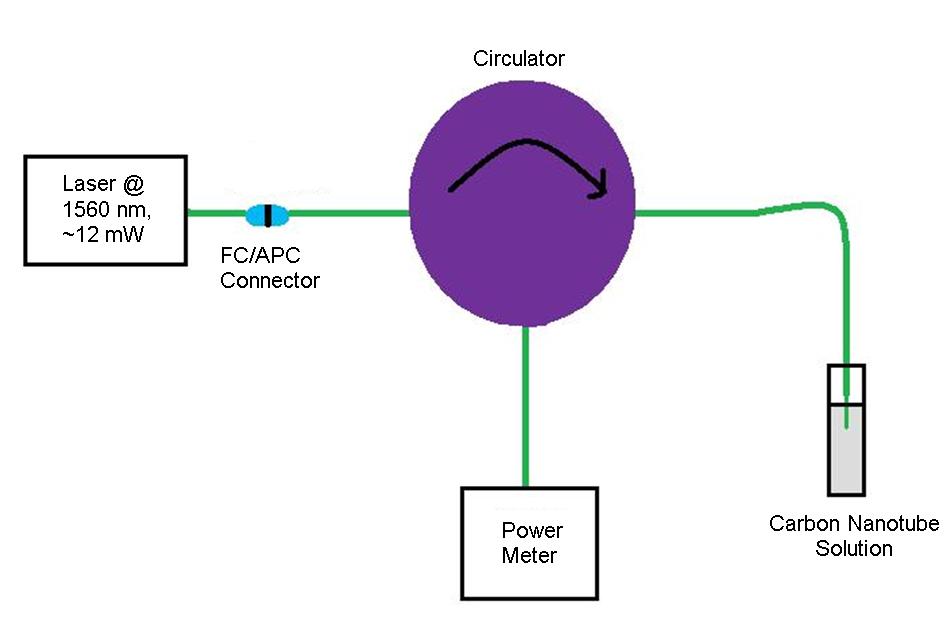

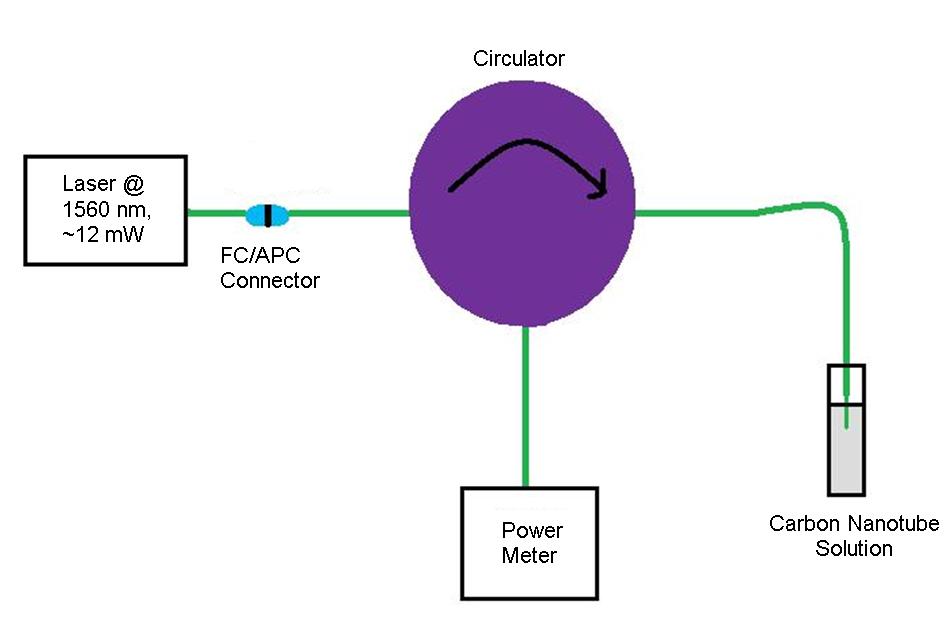

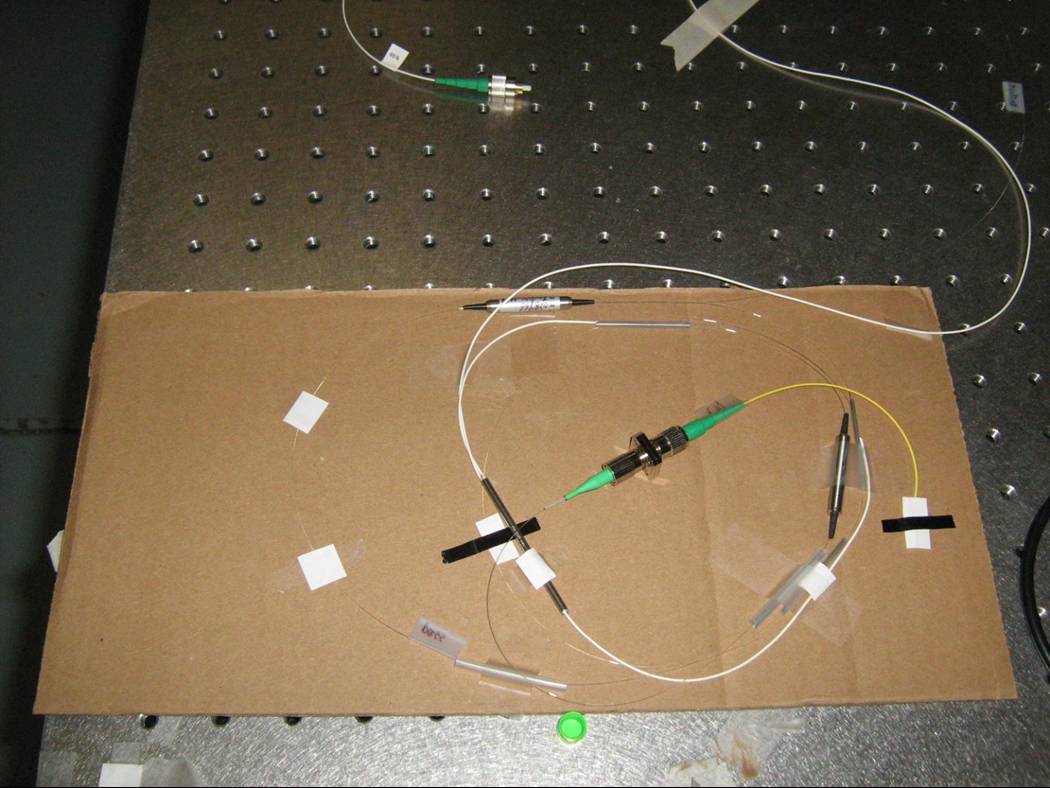

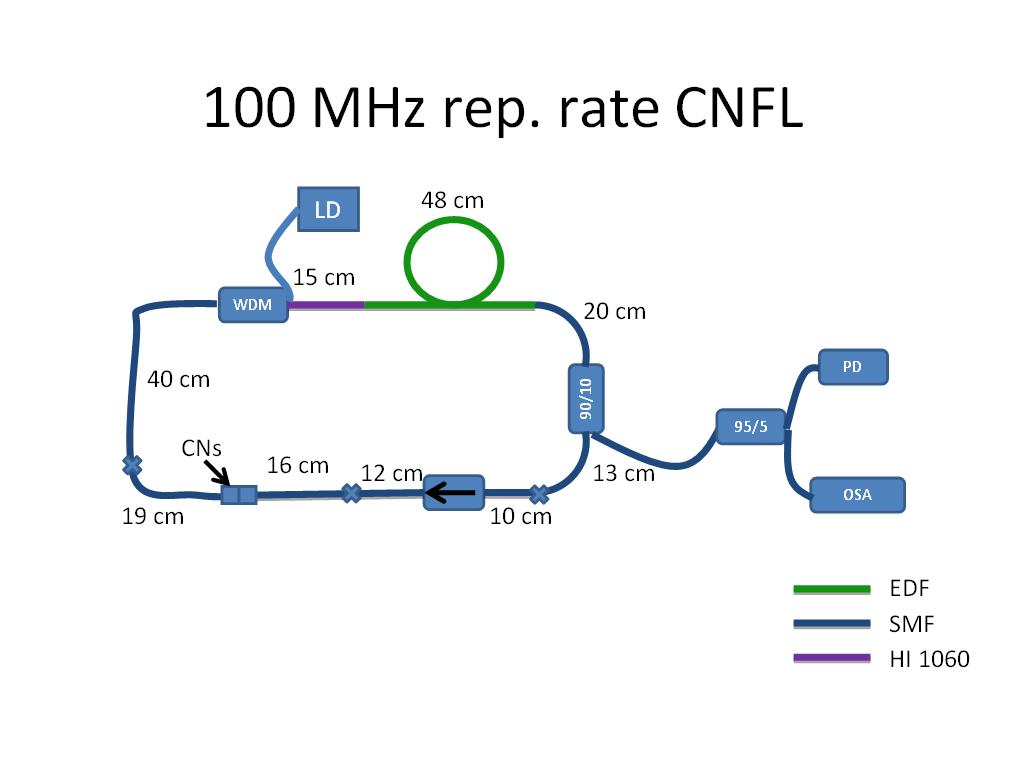

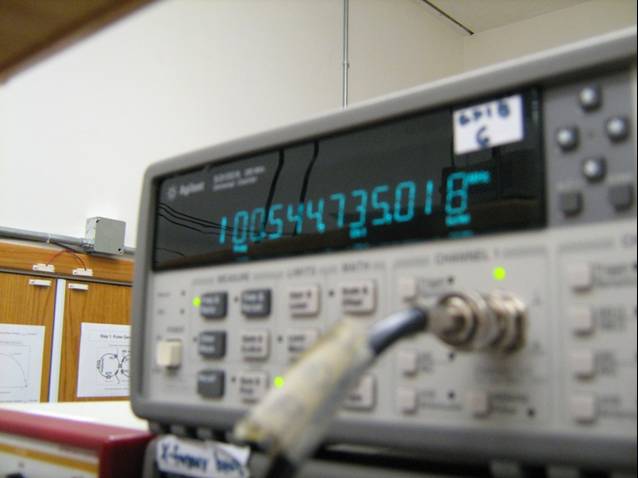

The components of the laser include a wavelength division multiplexer (WDM) which couples two different waves together, erbium doped fiber (EDF) to act as the gain medium, an isolator to prevent reflection, a 90/10 splitter in order to create an output and the connector with nanotubes deposited on the end to act as the saturable absorber which generates the mode-lock. See the links on the left in order to learn more about the physics of the laser.

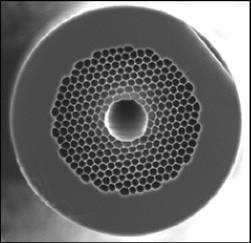

The next phase of my project involved exploring different possibilities regarding the deposition process. The first variability being tested is deposition on PBGF instead of SMF. PBGF is similar to SMF except that around its central core is a honeycomb of holes. Due to these holes, various gases, or in our case nanotubes, can be placed in the fiber dramatically changing its properties. In this new project, we hope to see if the nanotubes are drawn up into the fiber, and if the fiber can become a successful component in a CNFL. (2)

The source for photo is http://www.kirbyresearch.com/images/etc/pbgf

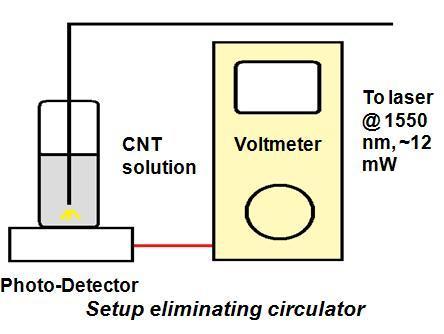

Since PBGF is so different from SMF, the splice between the two is extremely fragile. As a result, the deposition process was almost impossible since movement of the fiber meant the splice would instantly break. After intense amounts of frustration, and attempting to use a bare fiber connector, we decided to try a new method for measuring deposition.Due to the splice between SMF and PBGF, the reflected light from the splice overshadowed any change in reflected light. Because of this, Kristan Corwin had an inspired idea concerning a new method to determine deposition. Instead of looking at the reflected light, a photo-detector in conjunction with a voltmeter was placed directly underneath the solution in order to measure the transmitted light. Due to its new placement, the transmitted light should decrease dramatically in the shape of a plateau, opposite to what we expected in the reflection method.