Constructing an Extended Cavity Diode Laser

An REU project (currently) being done by Ryan

Price

Supervisor: Dr. DePaola

Welcome to

my 2008 REU research page. The following is a quick summary of a work currently

in progress:

Project: Over the summer, I am tasked with

constructing an extending cavity laser (ECL) that will be used within a

magneto-optical trapping configuration. For more information until I write a

nice general description, see wiki: Magneto-Optical Trap.

For the basis of our design, a reference paper concerning an extended

cavity diode laser built for Cs laser cooling is used as a starting point.

Because the experimental setup here at KSU uses Rb atoms, this requires a

re-engineering of the design to fit our specifications. So, essentially the

design and construction of the refit laser is the task at hand.

6-6-08:

The

following is a quick outline of the (presumable) steps involved in the laser

construction

1.

Researching

/ Basics of design

2.

Redesigning

for Current Experiment

3.

Parts

Acquisition and Construction

4.

Calibration

and Testing

During the

first week of working on the project, the first steps taken were to approach

step one through trying simple redesigns of the model ECL and looking for the

parts required for the project. By doing such I have a much better grasp on the

requirements and functionality of the laser model I have been tasked with

building.

6-13-08:

Week two so

far has been the creation for detailed designs on the computer. These models

created are going to be the reference model used during the machining and

construction stage to get the right dimensions and angles (mind you, optical

devices are particularly picky about exact geometries). If all goes well, parts

will start to be ordered and come in next week. However currently there is a

hold up in the process. Two parts required cannot be found easily or cheaply

for purchase so alternative sources for such parts may be found to keep the

project rolling on.

Oh yeah, and

a tornado hit the physics building… how cliché for a

summer in Kansas.

6-20-08:

Week three

is design week! I’m (slowly) learning how to use 3d tools to help model the

main casing to my laser design

My first day

trying to use this program, or as Dr. Weaver says jokingly, “Something to be proud

of (like) in kindergarten”.

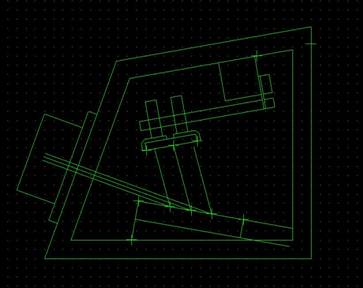

And then

things have progressed now to where someone in flatland would be proud!

Ok well then

let’s try again and try harder…

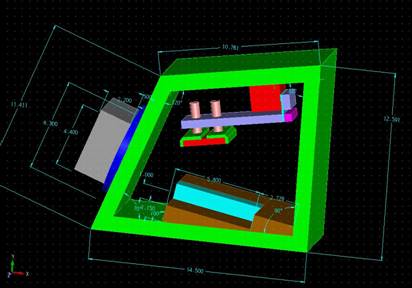

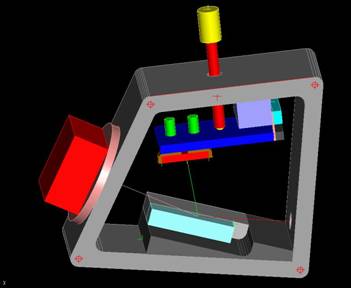

Now we have

3D! If only this were the end of the story. In the above picture, you can see

almost all the parts involved. For example, the big red block on the back is

the laser diode mount the green tubes are PZTs and the red thing below them the

prism that they control.

6-27-08:

So, because

of the tornado that hit us, the building had broken windows.

And because of broken windows and loose insulation, there is an asbestos fear

in the building that caused a building closure for 2 and half days. Kansas

seems to be the most eventful place I’ve worked thus far with tornados, power

outages and asbestos scares. So all together, not much progress was made in

updating the laser design unfortunately.

However, our

research group had time for an experiment run using the Kansas Laser Source (KLS) and I

got the opportune chance to watch (and help on a few parts!) the setup of the

experiment. It should be noted that being able to help out with operation in

KLS is quite the honor to me, considering the beam if brought to focus can

ionize air at a point (to the non-physics inclined, a familiar form ionized air

that you may be familiar with is lightning which has the ability to ionize the

air because of the enormous electric field created during discharge). Anyway,

as far as the laser goes, purchasing of parts is starting now, so hopefully construction

will be underway soon.

7-3-08: Parts, parts, and

more parts…

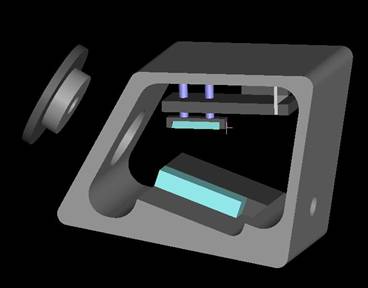

First, the

laser design itself is finished and en route to being created in the machine

shop. Note that the design has gone under many (minor) revisions. The most

important lessoned learned here is: never design in the metric system if

submitting items to a machine shop. So, introducing the final design:

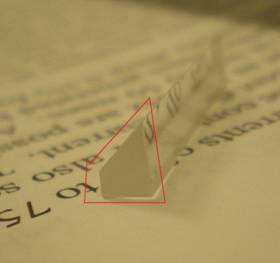

Secondly,

ordering parts has a downside. Especially when you get a prism that looks like

this:

When it

should look like this:

And why is

this prism a problem? Consider a light beam incident on the hypotenuse face and

an arbitrary location:

The purpose

of the prism is to act as the retro-reflector in the Litmann ECL design. So

with a large chunk of my prism missing (purple above), light that comes in at

this location or on the opposite side equidistant from the center of the face

is not reflected back properly. This is awful for two reasons:

1.)

The

laser power output will be significantly lowered

2.)

Nobody

makes prisms in nearly similar dimensions and thus there are no other prisms in

the entire land of the internet to be had to replace this one.

So in

summary, these prisms were promptly sent back to the manufacturer, and their

customer service I’m sure were simply thrilled to talk to me.

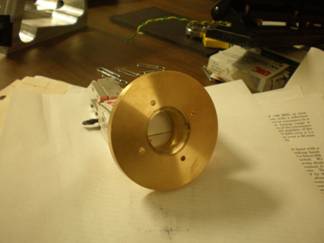

7-11-08:

Now that the

main casing for the laser will be made in the shop soon, I got head to the shop

myself to make an accompanying piece. Specifically, the one that holds the

laser mount to the case. More specifically, it is a flange that allows the

laser mount to be rotated such that the outgoing polarization of the laser

light incident upon the diffraction grating can be changed in such a way that

it controls the amount of light diffracted versus reflected. This in turn

controls how much light is kept in the extended cavity versus sent out of the

ECL.

So my

project this week was to start with something like this:

Throw it on

a lathe, put it through a saw, cut my finger, and drill some holes… and presto:

This piece

stands as a testament to my luck in the machine shop.

And because

of unfortunate happenstance, our project is somewhat on hold because the

specific type PZTs that control the prism rotation cannot be found at a

reasonable price. And one of the two companies that do sell them won’t even get

back to me with a price quote, even if I call them. Great customer service, I

do say.

And speaking

of customer service and shameless advertisement, an order from Thor Labs came today and in it, to my

surprise, there was a box full of ‘Lab Snacks’ with candy and food of all

kinds. Supposedly such a delightful thing comes with all of their shipments. After

dealing with other companies and their rotten prisms and not returning phone

calls, this really makes one’s day. Thor labs made a future customer out of me

by such a gesture, as trivial as it may sound.

7-18-08:

Our group

had another experiment using the KLS during this week, so for a few days I was

in and out of the lab watching/helping to set up parts of the experiment.

And last but

not least, the replacement prisms came back and they are exactly as horrid as

the first batch. The sales engineer tells me that ‘such deviations are common

from original specifications’. I agree, a five percent difference might be ok

to slide by, but when the dimensions are off by at least a quarter of the

advertised catalogue, then that’s just plain negligence. As it is closing in on

my last few weeks here at KSU, there is no way that I can get a replacement

prism custom ordered, so what to do is really up in the air.

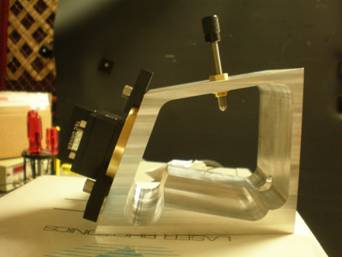

On the

machine shop note, I got to finish a portion of the sub-assembly that holds the

prism

Oh yeah, and

I have my main assembly too:

Now just to

put it all together…

7-25-08:

This week

has just been finishing up work in the shop and starting work on the electronic

sides for the laser diode mount. Thus far I have cables and am ready to go in

terms of connecting the cables and mounting the (really expensive) laser diode.

Final

Presentation and Report: An overall summary

of the work should be done around the end of the summer (beginning of August)

Pictures!

Other

Projects and Papers:

Although not the groundbreaking by any means, the following are some

papers I’ve had to write for various classes during my undergraduate career at

the University of Arizona Physics

Department.

Perhaps to someone they may provide some value or reference:

Spring 2008:

Measurement of Planck’s constant through Black Body Radiation

Analysis

Measurement of the Sodium D Emission Lines

Using a Michelson Interferometer

Fall 2007:

Experimental Determination of the Speed of

Light by the Foucault Method

Fall 2006:

Effect

of Matter Density in the Evolution of the Universe

Other Stuff (Lectures and such):

World wide internet:

JRM Laboratory (Home sweet home for

2 or so months)