Near-IR Extended Cavity Diode Laser for Methane Spectroscopy

Rudolph David Mayrhofer

University of Rochester

BS, Physics; BM, Applied Music - Clarinet

Mentored by Dr. Brian Washburn

The goal of this project is to build an extended cavity diode laser (ECDL) to be used in the detection of methane absorption lines. We are encouraged to study methane since it is a potent greenhouse gas as well as a substantial byproduct of the agricultural industry.

We aim to study the R3 absorption line of methane, which presents a particular challenge due to its width. The R3 line in methane is actually made of three separate absorption lines. These lines are separated by very small wavelengths, making them appear to be a single, broad line.

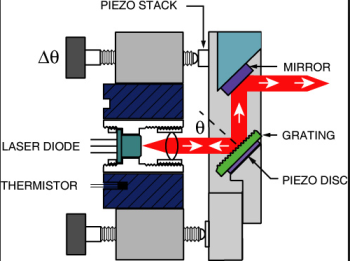

In order to effectively study this line, we will need a laser that can scan over this wide range. This laser also must produce a narrow spectrum of light, as this will give us better resolution of the line's features. We therefore choose the construct an ECDL, as it satisfies both of these requirements. The light from the laser diode is focused in a collimating lens and then diffracted by a grating. Some of the light is reflected back to the laser diode. This feedback significantly narrows the wide spectrum of the laser diode. The rest of the light is reflected by the grating to the mirror, which in turn sends the light to wherever it is needed in the experiment. A diagram of an ECDL is given below, as well as a picture of the setup we have built.

Fig. 1: The schematic for an extended cavity diode laser. From http://optics.ph.unimelb.edu.au/atomopt/diodes.html

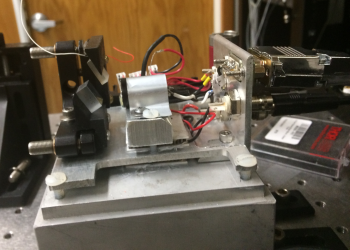

Fig. 2: A picture of our assembled ECDL.

Primarily, two aspects of the laser were improved during this program. The first was the cooling of the laser diode. The laser diode is placed on a large metal block and held in place by a thin sheet of aluminum. The metal block rests on a Peltier cooler. This Peltier cooler in turn rests on a large metal plate which is cooled by two more Peltier coolers. The heat generated from these coolers is transferred to the heat sink below them.

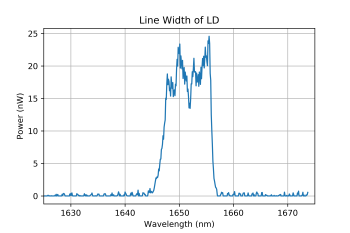

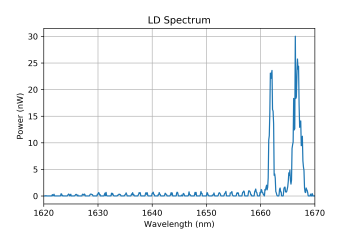

The second improved aspect of the ECDL is the mount for the grating and the mirror. Both parts were 3D printed and allow for some adjustment of the angles of grating and mirror. Once the new the mount is in place, the line width of the laser should narrow after some adjustment. Below we see the line width with and without the feedback from the grating. The spectrum has been narrowed, although there is an additional, unwanted line occurring even after the feedback has been provided.

Fig. 3: Line width of the laser without feedback from grating.

Fig. 4: Line width of the laser with feedback from the grating.

Further work on this ECDL includes eliminating this second line in the spectrum of the laser, testing the tuning range, and looking at the absorption of methane at the R3 line.

Acknowledgments

We would like to acknowledge John Lyons and Dr. Brett DePaola for their work on the initial design of the laser. Thanks must also go to Ottillia Ni and Dr. Kristan Corwin, who began this project at the KSU 2016 Physics REU program, and Timothy Moore who worked on the initial laser cooling system.

This project is funded by the National Science Foundation (NSF) and the Air Force Office of Scientific Research (AFOSR) through NSF grant number PHYS-1461251.