|

Purpose

Background

Materials Projects

Results

Conclusion |

| Purpose |

We are designing and testing

certain aspects of the Slow Monitoring and Recording system for the Double

Chooz neutrino project, focusing on the system of temperature and magnetic

field sensors which will monitor the status of the final detector.

|

|

Background |

|

Neutrinos |

| Neutrinos are elementary particles that weakly

interact with normal matter and move at nearly the speed of light. Their

properties make them important as a probe into the processes inside of the

Sun or in a nuclear reactor.

Reactor Neutrinos are produced by nuclear beta decay.

An example of b- decay

|

| Neutrino's Properties

|

- Elementary particle

- Interact through the weak force and gravity

- First theorized in1930 by Wolfgang Pauli

- First discovered in1956 by Clyde Cowan, Frederick Reines, F. B.

Harrison, H.

- W. Kruse, and A. D. McGuire.

- There are three types of neutrinos: electron (ne),

muon (nm)

and tau (nt)

- Electric charge: 0

- Spin: 1/2

|

| Neutrino Detection

2X |

| A process called inverse beta decay

is used to detect neutrinos.

The

process entails a proton and an antineutrino collision creating a positron

and neutron. (Shown in the equation above.)

Then, a positron and electron annihilate to produce two or more photons

which are detected. (Shown in the equation above.)

|

|

Double Chooz |

| Double Chooz is investigating the

value of the q13 neutrino mixing angle. They want to measure this angle

within the range of 0.2 to 0.03-0.02 within three years of data taking. In

order to achieve this scientific goal the detectors need monitoring systems

to ensure 1% or less error in measurements.

|

| Materials |

|

HMC2003 Three-Axis Magnetic Sensor Hybrid

DS18S20 High-Precision 1-Wire Digital Thermometer

DS2450 1-Wire Quad A/D Converter

Buffer Oil

Thermally Conductive Epoxy

Clear Epoxy

Solenoids

Clear Acrylic

|

| Projects |

|

Testing and calibrating sensors

Compatibility testing of components and epoxies with buffer oil

Designing the Set/Reset circuit and developing a software interface

Fabricating the mount unit for sensors

Designing and building the integrated circuit board

Testing prototype

|

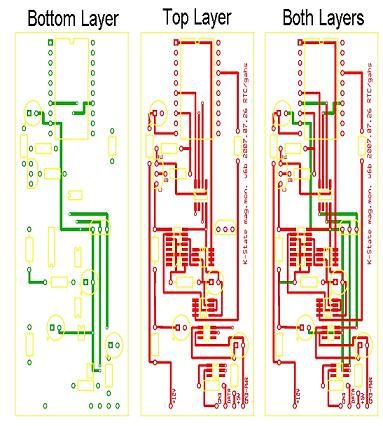

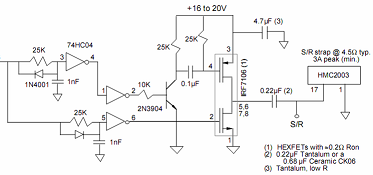

| Set/Reset Circuit |

|

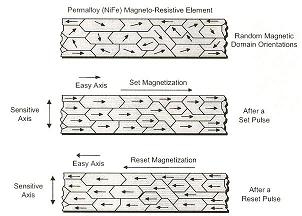

When the magnetic sensors encounter a large magnetic field, the magnetic domains begin to skew, producing inaccurate readings.

Solution: Create a circuit which will reset the domains periodically.

|

|

Diagram for a S/R Circuit

|

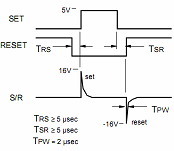

Set/Reset Pulse

|

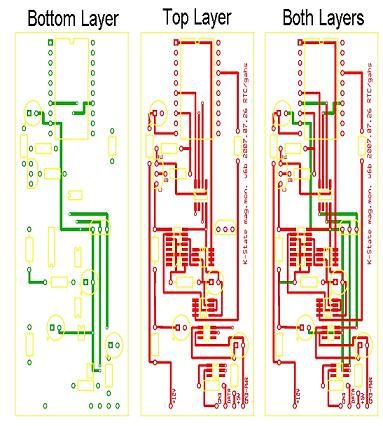

Prototype PCB for Sensors

|

|

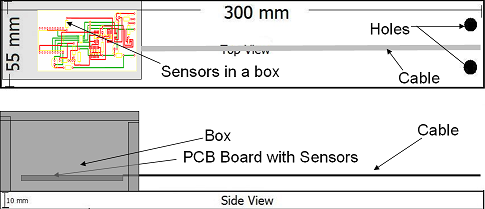

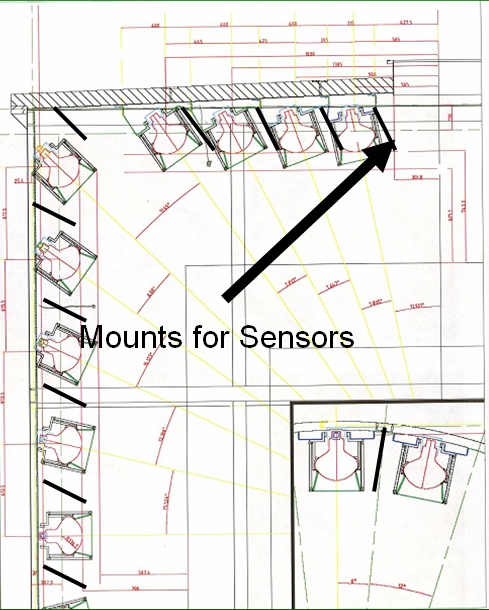

Prototype Mount for Sensors

|

Preliminary Placement of Sensors in the Tank

|

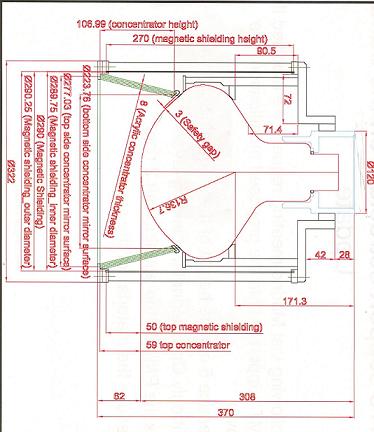

PMT Dimensions

(Length in mm) |

| Results |

|

|

Oil spectrum data has shown that in the oil exposed to our Teflon coated wire there is a small increase in absorbance around blue because of the printed letters on the insulation. (Graph shown above.)

|

|

|

Temperature sensors covered in thermally conductive epoxy reacts to changes faster than the clear epoxy. The fastest reaction time came with no epoxy at all. (Graph shown above.)

|

|

|

When compared with a pre-calibrated magnetic field sensor, ours was found to be very accurate. (Graph shown above.)

|

|

|

Testing over several days has shown the program can run for an extended period. (Graph shown above.)

|

Conclusion

Compatibility tests present evidence that the cable, temperature sensor, clear epoxy, and thermally conductive epoxy have little effect on the oilís absorption spectrum. Testing shows that a greater precision is gained when a set/reset circuit was triggered before with an ADC. |